Despite its substantial production capacity of 7.5 million tons per year, HT1 faces challenges as 98-99% of its consumption is concentrated in the domestic market, primarily in the Southern region.

The market advantage

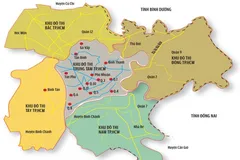

HT1, as the largest production unit under the Vietnam Cement Corporation (Vicem), caters to markets in Ho Chi Minh City, Binh Duong, Dong Nai, and Long An. The Southern region, being the second-largest cement consumption center in Vietnam, demands an average of 21-23 million tons annually. However, the region faces a supply shortage due to its lower reserves of limestone and clay, necessitating the import of over 10 million tons of cement from the North each year.

In comparison to the Northern region, Southern enterprises, including HT1, enjoy advantages in consumption, higher selling prices (attributed to input cost differences), and primarily compete through their ability to scale and manage production costs efficiently. Despite these advantages, HT1's current financial woes highlight challenges in translating these benefits into sustained profitability.

HT1's struggle with financial losses and imbalance underscores the complexity of the cement industry in the Southern region. Despite its significant production capacity and market advantages, the company must navigate challenges related to supply shortages, market dynamics, and internal financial stability. Addressing these issues will be crucial for HT1 to not only weather the current difficulties but also emerge as a financially sound and sustainable player in the Southern cement market.

Facing Operational Turmoil

While not contending with the competitive landscape experienced by Northern enterprises, HT1 encounters frequent instability in its production and business operations. One of the persistent challenges is the short-term financial imbalance, where the value of short-term debt has consistently surpassed that of short-term assets. By the close of 2022, HT1's short-term debt had escalated to VND 4,255 billion, overshadowing short-term assets, which only amounted to VND 2,373 billion. This imbalance strains cash flow as HT1 often resorts to rolling over short-term debt, further exacerbated by a substantial portion (30-33%) being payables to related and unrelated parties. Despite demonstrating the ability to utilize long-term suppliers' capital during significant increases in accounts payable, a majority (consistently over 69% from 2018-2022) of these amounts originate from units not affiliated with Vicem, adding negative pressure to HT1's cash flow, particularly in the face of sudden shifts in debt policy.

Analysis by FPT Securities Company (FPTS) reveals a sudden spike in HT1's 2022 inventory value, reaching VND 1,188 billion (a surge of 44.8%). Key components of this increase include raw materials at VND 573 billion (up 48.8%) and finished products at VND 492 billion (up 59.8%). The primary driver behind this surge is businesses augmenting coal inventories to ensure uninterrupted production amid escalating coal prices. Furthermore, as per current accounting policies, the value of finished products is determined by the cost of raw materials, direct labor, and general production costs. This methodology has inflated HT1's raw materials and finished products inventory values, especially given the sharp rise in input raw material costs in 2022.

Notably, HT1's 2022 payables have experienced a significant uptick to VND 1,434 billion (an increase of 18.7%). The major contributor to this rise is payables to related parties, escalating from VND 292 billion to VND 448 billion, driven by HT1's increased procurement of coal and transportation services from Vicem. Despite this surge, HT1 maintains a high number of payable days, ranging from 53 to 63 days during the period 2018-2022. This is facilitated by the policy of rescheduling debt from internal suppliers. Consequently, HT1 accrues more negative cash turnover days, alleviating the pressure on short-term loans required to finance working capital.

Potential Risks and Challenges

HT1, the leading cement production enterprise in the Southern region, is grappling with significant challenges, as indicated by its third-quarter financial report. Net revenue from sales and service provision experienced a notable decline of 30.2%, amounting to VND 1,576 billion, while the gross profit on sales and service provision decreased by over 25%, reaching VND 142 billion. Particularly concerning is the surge in financial costs, which escalated by 42.5% to VND 44.6 billion during the same period. This increase is driven by a sharp rise of 81.8% in interest expenses, reaching VND 32.2 billion, coupled with a 2.7% uptick in business management costs, reaching VND 63.2 billion. Consequently, HT1 reported a third-quarter loss exceeding VND 10.3 billion, marking the second consecutive quarter of losses in 2023. The accumulated losses for the first nine months of 2023 amounted to over VND 37 billion.

Analysts at FPTS forecast a further decrease in HT1's consolidated gross profit margin for 2023 and 2024, with anticipated declines of 6.7% and 7.6%, respectively. The outlook for 2023 suggests a pre-tax loss of VND 27.7 billion, reflecting a substantial decrease of 108.6%. However, a return to profitability is expected in 2024, with a projected pre-tax profit of VND 42.7 billion. This optimism hinges on several key factors, including a gradual reduction in coal prices, a recovery in consumption demand, and the avoidance of sudden increases in interest expenses.

Despite the positive projections, HT1 remains exposed to various risks that could impede its path to profitability. Notably, the risk of increased sanctions looms due to the overexploitation of limestone and clay production. Currently exceeding the allowed output by 30-40%, HT1 faces the prospect of more severe fines, affecting both revenue and profits. Another significant risk is the annual cost associated with spare parts and maintenance, ranging from VND 45-65 billion per year, equivalent to 0.5-0.7% of revenue. Aging kilns and stations, exceeding or nearing their maximum productive life, pose a high risk of failure. A line error could force HT1 to temporarily halt production for up to two months, impacting output and product quality. These risks underscore the challenges HT1 must navigate to achieve sustained profitability in the coming years.